First let me say that none of the following pots are yet for sale.

OK. I was not going to do any more of these biweekly updates until August or so. I intended to do the six week or so updates with new pots for sale instead. I have been glazing so I should have a lot of pots to post for sale. To this point I would describe my glazing efforts as "too time consuming and elaborate, too experimental- my ideas exceed my knowledge of how the glazes are going to perform- and at times very disappointing and at other times, very rewarding."

I fired a load Thursday night. I let it cool down until Saturday morning. I get up early in my jams go down and open the kiln. Just looking at the top shelf, my reaction is, "DAMN!" And that is not "DAMN!" as in damn good. When kiln loads like this come out, it throws me off for a day or two. It puts me in a quandry. "What happened, why, how????" I can not afford this. So to take my mind off the results, I thought I would take some therapeutic time and generate a web page and show you the downside of potting. And if you buy my pots, one way or another you pay for my bad results. I factor everything in price. And every potter experiences things like this. Robineau, Rhead, whoever, have all opened kilns and said the same "DAMN!" thing.

The first piece is nice. A fine, small, clean rain pot.

Then there is a bigger rain pot that has been fired twice and it minor problems.

Then, my pot that I felt best about reveals itself and looks fantastic. This is a pot I plan to fire twice, possibly three times. And the first glazing looks great so it is on it's way to greatness. Look at that moon!!!

Then I lift it out and inspect it more closely and...

DAMN!

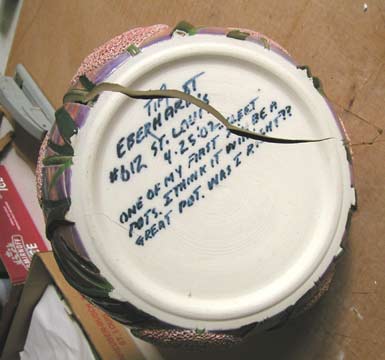

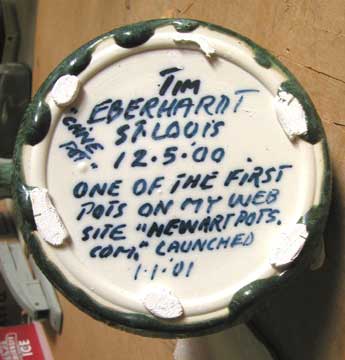

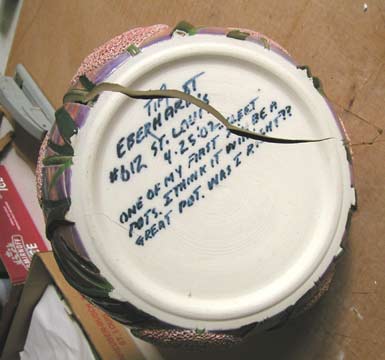

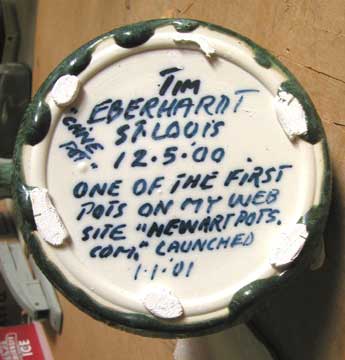

Admittedly, I don't get that kind of cracking very often. But this glazing cycle is different from what I have done heretofore. I am glazing all my snow and sleet pots at least twice, most three times. And that is always taking a chance. I would expect a crack like the one above on the second or third firing, not the first. Anyway, onward.... Next, one of my swirl gourds. This one- and it is marked on the bottom as such- is the best shape of all the swirl gourds I have made.

DAMN!

Look closely at the photo and you will see the pot is fused to the tile it was sitting on all the way around the pot. You put pots on tiles when you fire so that if you get a glaze run it will not fuse itself to the 50 dollar kiln shelf. Why did this happen? I glazed the pot by hand and then for some reason gave it a very light dusting of another glaze. I never anticipated that little bit of extra glaze you cause the other glaze to flux out early and turn to liquid. I might- and I mean might- be able to get that pot off that tile , but it will take a couple hours. And it is an "if to come" situation. DAMN! Onward...

Next, a locust tree pot with seed pods and falling leaves. Again, I take a chance and use a new glaze thinking I know how it will perform. This pot can be salvaged by reglazing and firing it again. As it stands now, it lacks a LOT in the glaze department. The sky is too harsh. The seed pods don't even come close to reading as seed pods. The yellow leaves are the biggest problem.... I'll said "DAMN" when I saw this one too. But I'll refire and keep my fingers crossed.

Onward.... I fired these two chive pots nearly two years ago. I was not paying close enough attention when loading the kiln. They kissed, the glaze at that spot ran and fused the pots together and to each of the tiles they were sitting on. That got a "DAMN" two years ago. Well, I had half a shelf of space in the last kiln load, am in desperate need of pots, so I decided to fire them again and set them up on a pile of tiles so when the glaze melted they would separate and lift themselves off the tiles they were fused to. Taking a chance with a tricky idea. It worked to some degree. They separated and one cleared itself of the tile. One is still stuck to a tile and they both have numerous glaze drips on the foot. Again, it will take hours to salvage they pots; they are beautiful pots. "DAMN," but there is hope.

Next, the two biggest disappointments. These are 14" pots and it is the first of three glazings. But I expected a better look that this. I was trying to get one of those Frederick Church red and blue and purple sunset skies. Shoot, it is embarrassing just to show you these.

Now, there is hope. But damn, it is going to be difficult to turn these around. Could this load continue on this path? Yes. Next a little gourd that was fired the second time. The glaze ran a little bit and fused it to the tile. I tapped it off the tile and it took a couple of small pieces of the pot along the way. You turn it over and look at it and you would probably say "Ohhh, too bad."

Next, finally some good news. This snow pot was fired twice and improved dramatically. It was really dubious after the first firing. Now it's OK.

Next, better news. The highlight of the load. No description necessary.

The next pot, I knew I had under control and I new it would be a beauty from the start. You might remember, this was one of those great seven pots I threw with my last 60# of clay. It's a great pot.

There is a snake in the grass round the bottom of the pot. It is really a beauty.

Next something really different. I did this thinking about the Overbeck sisters and a potter from Farmington, Missouri. I threw the pot and took a pencil and outlined flowers and leaves, leaving a white porcelain line to separate colors. This was on the bottom of the kiln and when I saw it I said "DAMN, that's great." It looked better than I ever expected. I mean -as my 11 year old says, "SWEET!" I pull it out and examine it. PERFECT! People are going to fight over this one in Zanesville.

After all the pots are on the table and I am looking at them again, I pick this one up to console myself and think, "I wonder what Hannah Overbeck would think..." and I notice them. There are spider lines finer than hair on one side of the pot. I tap it again to see if it if cracked. No, it rings when I tap it. It is not cracked. But DAMN, those spider lines move it from the GREAT POT catagory to the IT'S GOT A PROBLEM catagory. I have to explain the problems anytime someone picks it up. And everyone will pick this pot up!!! DAMN!

Ok, last is Terry's little frog. It is nice. I had hpoed the glazes would have mixed a little better. Well, I can reglaze and refire, no problem. I turn it over and it has a crack that I don't dare subject to the fire again. It's a crack that doesn't affect the look of the frog so it is not really a flaw, but it does make me stop thinking about trying to improve it. I am happy with it and that's OK.

I am sure Terry will love it.

So, here's the tally. (I just stopped what I was typing, reviewed this web page and tallied the pots as "YES", "MAYBE-needs work", or "TOTAL LOSS.") My reaction? "DAMN!" Four fine YES pots. Ten! MAYBES. One TOTAL LOSS. I can not afford to have this happen when I only have two and a half weeks to glaze. DAMN!

HOME------NEW POTS FOR SALE------OLD POTS NOT FOR SALE------POTTER INFO------CONTACT AND SALES------EXHIBITIONS------MOST CURRENT WORK------CATCH-ALL PAGE

OK. I was not going to do any more of these biweekly updates until August or so. I intended to do the six week or so updates with new pots for sale instead. I have been glazing so I should have a lot of pots to post for sale. To this point I would describe my glazing efforts as "too time consuming and elaborate, too experimental- my ideas exceed my knowledge of how the glazes are going to perform- and at times very disappointing and at other times, very rewarding."

I fired a load Thursday night. I let it cool down until Saturday morning. I get up early in my jams go down and open the kiln. Just looking at the top shelf, my reaction is, "DAMN!" And that is not "DAMN!" as in damn good. When kiln loads like this come out, it throws me off for a day or two. It puts me in a quandry. "What happened, why, how????" I can not afford this. So to take my mind off the results, I thought I would take some therapeutic time and generate a web page and show you the downside of potting. And if you buy my pots, one way or another you pay for my bad results. I factor everything in price. And every potter experiences things like this. Robineau, Rhead, whoever, have all opened kilns and said the same "DAMN!" thing.

The first piece is nice. A fine, small, clean rain pot.

Then there is a bigger rain pot that has been fired twice and it minor problems.

Then, my pot that I felt best about reveals itself and looks fantastic. This is a pot I plan to fire twice, possibly three times. And the first glazing looks great so it is on it's way to greatness. Look at that moon!!!

Then I lift it out and inspect it more closely and...

DAMN!

Admittedly, I don't get that kind of cracking very often. But this glazing cycle is different from what I have done heretofore. I am glazing all my snow and sleet pots at least twice, most three times. And that is always taking a chance. I would expect a crack like the one above on the second or third firing, not the first. Anyway, onward.... Next, one of my swirl gourds. This one- and it is marked on the bottom as such- is the best shape of all the swirl gourds I have made.

DAMN!

Look closely at the photo and you will see the pot is fused to the tile it was sitting on all the way around the pot. You put pots on tiles when you fire so that if you get a glaze run it will not fuse itself to the 50 dollar kiln shelf. Why did this happen? I glazed the pot by hand and then for some reason gave it a very light dusting of another glaze. I never anticipated that little bit of extra glaze you cause the other glaze to flux out early and turn to liquid. I might- and I mean might- be able to get that pot off that tile , but it will take a couple hours. And it is an "if to come" situation. DAMN! Onward...

Next, a locust tree pot with seed pods and falling leaves. Again, I take a chance and use a new glaze thinking I know how it will perform. This pot can be salvaged by reglazing and firing it again. As it stands now, it lacks a LOT in the glaze department. The sky is too harsh. The seed pods don't even come close to reading as seed pods. The yellow leaves are the biggest problem.... I'll said "DAMN" when I saw this one too. But I'll refire and keep my fingers crossed.

Onward.... I fired these two chive pots nearly two years ago. I was not paying close enough attention when loading the kiln. They kissed, the glaze at that spot ran and fused the pots together and to each of the tiles they were sitting on. That got a "DAMN" two years ago. Well, I had half a shelf of space in the last kiln load, am in desperate need of pots, so I decided to fire them again and set them up on a pile of tiles so when the glaze melted they would separate and lift themselves off the tiles they were fused to. Taking a chance with a tricky idea. It worked to some degree. They separated and one cleared itself of the tile. One is still stuck to a tile and they both have numerous glaze drips on the foot. Again, it will take hours to salvage they pots; they are beautiful pots. "DAMN," but there is hope.

Next, the two biggest disappointments. These are 14" pots and it is the first of three glazings. But I expected a better look that this. I was trying to get one of those Frederick Church red and blue and purple sunset skies. Shoot, it is embarrassing just to show you these.

Now, there is hope. But damn, it is going to be difficult to turn these around. Could this load continue on this path? Yes. Next a little gourd that was fired the second time. The glaze ran a little bit and fused it to the tile. I tapped it off the tile and it took a couple of small pieces of the pot along the way. You turn it over and look at it and you would probably say "Ohhh, too bad."

Next, finally some good news. This snow pot was fired twice and improved dramatically. It was really dubious after the first firing. Now it's OK.

Next, better news. The highlight of the load. No description necessary.

The next pot, I knew I had under control and I new it would be a beauty from the start. You might remember, this was one of those great seven pots I threw with my last 60# of clay. It's a great pot.

There is a snake in the grass round the bottom of the pot. It is really a beauty.

Next something really different. I did this thinking about the Overbeck sisters and a potter from Farmington, Missouri. I threw the pot and took a pencil and outlined flowers and leaves, leaving a white porcelain line to separate colors. This was on the bottom of the kiln and when I saw it I said "DAMN, that's great." It looked better than I ever expected. I mean -as my 11 year old says, "SWEET!" I pull it out and examine it. PERFECT! People are going to fight over this one in Zanesville.

After all the pots are on the table and I am looking at them again, I pick this one up to console myself and think, "I wonder what Hannah Overbeck would think..." and I notice them. There are spider lines finer than hair on one side of the pot. I tap it again to see if it if cracked. No, it rings when I tap it. It is not cracked. But DAMN, those spider lines move it from the GREAT POT catagory to the IT'S GOT A PROBLEM catagory. I have to explain the problems anytime someone picks it up. And everyone will pick this pot up!!! DAMN!

Ok, last is Terry's little frog. It is nice. I had hpoed the glazes would have mixed a little better. Well, I can reglaze and refire, no problem. I turn it over and it has a crack that I don't dare subject to the fire again. It's a crack that doesn't affect the look of the frog so it is not really a flaw, but it does make me stop thinking about trying to improve it. I am happy with it and that's OK.

I am sure Terry will love it.

So, here's the tally. (I just stopped what I was typing, reviewed this web page and tallied the pots as "YES", "MAYBE-needs work", or "TOTAL LOSS.") My reaction? "DAMN!" Four fine YES pots. Ten! MAYBES. One TOTAL LOSS. I can not afford to have this happen when I only have two and a half weeks to glaze. DAMN!